Notes to a video lecture on http://www.unizor.com

Direct Current Motors

Direct current (DC) motors are used where the sources of electricity produce direct current, like batteries.

For example, DC motors work in car engine starter, computers, toys, drones and many other devices.

We will concentrate on principles of their work without going into many

details. Basically, we will describe these motors as they were first

thought of by their inventors. Obviously, initial ideas were further

improved by many people and improvements are still introduced after more

than 200 years after their invention, but the basic ideas are still

there.

Let's start with the idea of the DC motor.

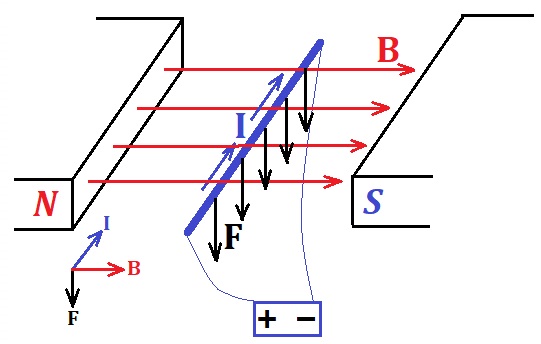

The beginning of a development of a DC motor is associated with a simple

experiment we described before - the one that demonstrated the Lorentz

force on a current in a magnetic field.

If the direction of a current I is perpendicular to a direction of magnetic field lines B,

the magnetic field "pushes" the conductor that carries this current in a

direction perpendicular to both magnetic field lines and a current by

force F.

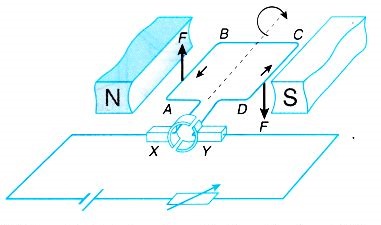

The first modification of this experiment was to use a rectangular wire

frame instead of a straight line conductor and let it spin around an

axis. The force exerted by a magnetic field will act on both sides of a

wire frame that are perpendicular to magnetic lines in opposite

directions, creating a rotational momentum, so the frame with rotate.

The force F of a magnetic field "pushes" segment AB up and segment CD, where the electric current goes in an opposite to segment AB direction, is "pushed" down by this force. This creates a rotational momentum.

The problem is, the rotation will stop when the wire frame plane will be

perpendicular to a direction of a magnetic field, because the forces

exerted by a magnetic field on both sides of a wire frame AB and CD

will no longer create a rotating momentum, they will act against each

other within the wire frame plane and after a short oscillation caused

by a rotational inertia the rotation stops.

On the picture above, when the plane of a wire loop reaches the position perpendicular to the magnetic field force, the segment AB will be on the top and the magnetic field force F will "push" this segment up. Segment CD will be on the bottom and the magnetic field force F

will "push" this segment down. Both forces are acting within the same

plane with the axis of rotation and nullify each other. No rotational

momentum is created.

Our next improvement is related to overcoming this problem.

What happens if exactly at the moment when our wire frame plane is

perpendicular to magnetic field, when the forces exerted by a magnetic

field no longer create a rotational moment, we switch off the electric

current in a wire and a very short moment later we switch it on, but in

the opposite direction of the electric current?

First of all, the rotation will continue by inertia during the time

electricity is off. Then, we turn the electric current on but in

opposite direction. That means, the direction of the magnetic field

force will change to an opposite. Segment AB will be "pushed" down, segment CD

will be "pushed" up. Since the wire frame has passed the point of

perpendicularity to magnetic field by rotational inertia during electric

current off time, the newly formed magnetic field forces will create a

rotational moment and the direction of rotation will be the same as

before.

Our frame will continue the rotation in the same direction until segment AB will be on the bottom and segment CD - on the top.

At that moment we will do the same switching off the electric current to

let our frame pass the perpendicular position towards the magnetic

field force, and a very short moment later we switch electric current on

in an opposite direction. Now segment AB will be "pushed" up again, segment CD will be "pushed" down, which will allow to complete the cycle of rotation and the rotation will continue in the same direction.

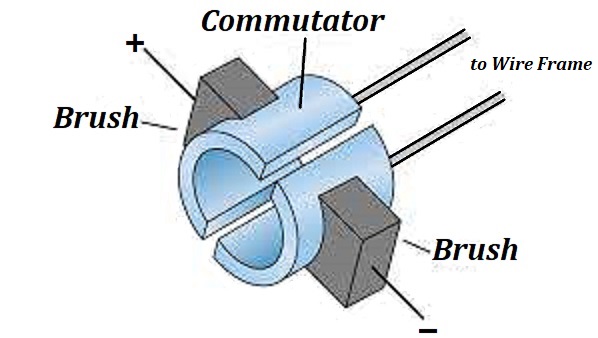

All we need is to explain how to switch the direction of an electric current.

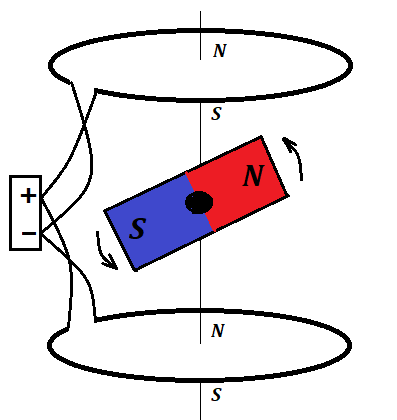

Here is a drawing of this simple device called commutator.

Direct current comes through brushes to a commutator and to a revolving

frame connected to it. As this construction revolves, the brushes lose

the contact with a commutator for a very short period, then again touch

the commutator, but with opposite poles.

That's how we change the direction of the current that forces the frame to constantly rotate in the same direction.

The inner rotating part of this type of a DC motor is called rotor, the outer stationary part with a magnet is called stator.

The detail implementation of this design of a DC motor is outside the scope of this course. Our purpose is to convey the idea.

The weak part of a DC motor design with brushes is that these brushes

wear out with time and are the source of sparks, which might be

prohibitive in some environments. Plus, they are noisy.

With development of electronics inventors came up with a better design

that does not involve brushes at all, rotation is accomplished without

any mechanical switches.

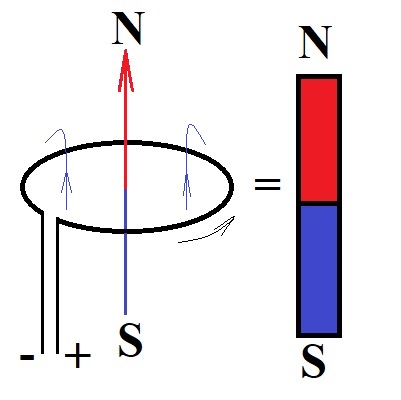

First step on the design of this brushless DC motor is to realize that

we have to invert the functionality of permanent magnet and a wire

frame. The need for a commutator with mechanical brushes was related to the fact that electric circuit was rotating.

Let's invert roles and put two parallel wire frames on opposite ends of a circle as a stator and a permanent magnet on an axis in the middle as a rotor.

Recall that a wire loop with direct current running through it acts like a magnet

Putting two such loops on opposite ends of a stator creates a magnetic

field and a freely rotating permanent magnet in between will have to

turn to align itself with the field of these two wire loops

If at the moment our permanent magnet aligns with magnetic field of both

wire loops we change the direction of electric current in the loops to

an opposite, thus changing the polarity of the magnetic field they

generate, the permanent magnet in between will have to continue the

rotation until it will align again. Repeating this cycle creates the

rotation of a permanent magnet.

This rotation will not be smooth. The force of magnetic field attraction

will create a stronger moment of rotation when the direction of the

permanent magnet is perpendicular to a direction of the magnetic field

of the loops. This can be improved by certain additional details

described below.

The changing of the direction of the current in the wire loops now is

much easier than in the previous design because the wires are not

moving. Simple electronic switch working off some kind of a marker on a

rotating permanent magnet can signal its position and trigger the switch

of direction of the current.

Basically, the idea is finished here. But some very important improvements should be mentioned.

1. Instead of a single wire loop we can use a copper coil around an iron

core to make the magnetic field of this electromagnet stronger.

2. Instead of a pair of such electromagnets with switching the direction

after the permanent magnet in the middle turns by 180°, we can use two

pairs and properly engage another pair after 90° turn, switching off the

previous pair, thus creating a rotating magnetic field that results in a

smoother movement of a permanent magnet rotor. Even better, we can use

three pairs of electromagnets and engage another pair after each 60°,

switching off the previous two pairs. This will allow even smoother

rotation. In some DC motors they use even six pairs of electromagnets,

which results in a very uniform rotation with practically constant

angular speed.

The electronic switches that engage and disengage the coils can be designed for any type of coil arrangement.

3. Instead of a bar permanent magnet inside the circle of electromagnets

we can use a ring permanent magnet outside it. It creates a better

response to a revolving magnetic field of a stator, the rotation will be

smoother because of inertia of a rotating ring.

With all the above improvements the DC motor used in hard disk of computers and other devices looks like the one below

This DC motor has 9 electromagnets sequentially engaged after each 40° turn of a rotor.

Rotor is a ring-shaped permanent magnet that rotates around the electromagnets.

A marker on the rotor sends a signal to an electronic switch to indicate

the position of a rotor, which is used by electronics on the attached

board to properly engage the electromagnets of a stator.

The most important detail of this design of a DC motor is the rotating

magnetic field achieved through purely electronic means without any

moving parts. This results in a smooth rotation of a rotor made of a

ring permanent magnet around a stator.

No comments:

Post a Comment